Our Commitment

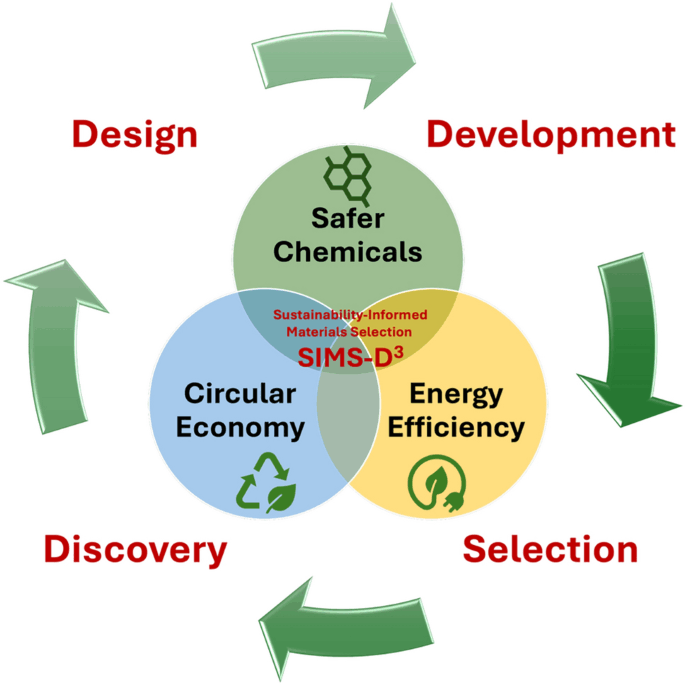

Colouring the world shouldn’t come at the cost of the planet. At MYNAA, we’re redefining what responsible manufacturing means for the plastic industry. Every batch we produce is guided by the idea of “Less Waste, More Value.”

We’re investing in energy-efficient extrusion, recyclable carrier polymers, and clean pigment technologies all to ensure that our colours last, but their impact doesn’t. Sustainability is not just a part of our process it’s the reason we innovate.